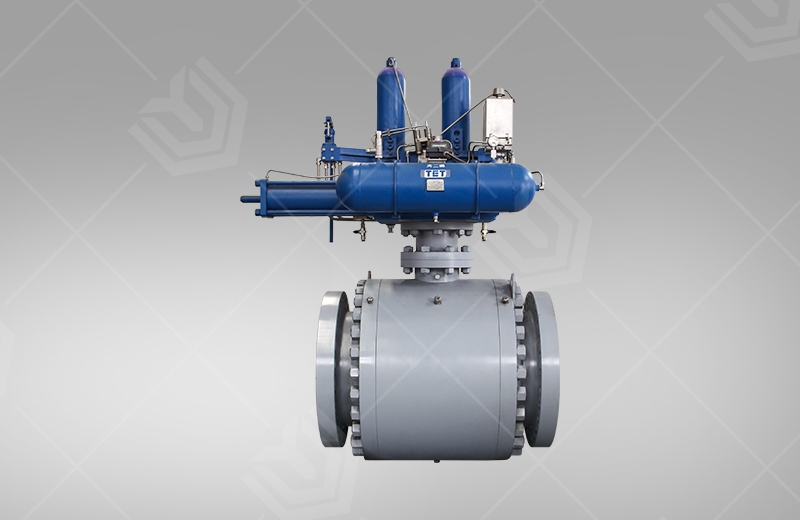

Product Detail

Product Design Features

Material of main parts

| NO | Part Name | Grey cast iron | WCB | Stainless acid-resistant cast steel | Ultra-low carbon stainless acid-resistant cast steel | ||

| Z | C | P | R | PL | RL | ||

| 1 | Body/bonnet | HT250 | WCB | CF8 | CF8M | CF3 | CF3M |

| 2 | Ball/Stem | WCB | CF8 | CF8M | CF3 | CF3M | |

| 3 | Lining/Seat | PCTEF(F3),FEP(F46),PFA(SolubleF4),PP,PO | |||||

| 4 | Packing gland | WCB | CF8 | CF8M | CF3 | CF3M | |

| 5 | Packing | PTFE(F4) | PTFE(F4) | PTFE(F4) | |||

| 6 | Bracket | 35 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | |||

| 7 | Bolt | 35 | Cr17Ni2 | 1Cr18Ni2 | |||

| 8 | Fastening nut | 45 | 0Cr18Ni9 | 0Cr18Ni9 | |||

| 9 | Operation handle | WCB | WCB | WCB | |||

Operation handle(PN10)

| DN(mm) | NPS(inch) | L | D | D1 | D2 | f | b | Z- φd | D0 | H | WT(kg) |

| 15 | 1/ 2 | 140 | 95 | 65 | 45 | 2 | 14 | 4-14 | 120 | 80 | 3 |

| 20 | 3 /4 | 140 | 105 | 75 | 55 | 2 | 16 | 4-14 | 140 | 90 | 3.9 |

| 25 | 1 | 150 | 115 | 85 | 65 | 2 | 16 | 4-14 | 160 | 100 | 4.5 |

| 32 | 1-1 /4 | 165 | 135 | 100 | 78 | 2 | 18 | 4-18 | 160 | 110 | 6.5 |

| 40 | 1-1/2 | 180 | 145 | 110 | 85 | 3 | 18 | 4-18 | 200 | 120 | 8 |

| 50 | 2 | 200 | 160 | 125 | 100 | 3 | 20 | 4-18 | 250 | 135 | 11 |

| 65 | 2-1 /2 | 220 | 180 | 145 | 120 | 3 | 20 | 4-18 | 300 | 145 | 15.5 |

| 80 | 3 | 250 | 195 | 160 | 135 | 3 | 22 | 4/8-18 | 350 | 180 | 19 |

| 100 | 4 | 280 | 215 | 180 | 155 | 3 | 22 | 8-18 | 240 | 195 | 26 |

| 125 | 5 | 320 | 245 | 210 | 185 | 3 | 24 | 8-18 | 500 | 210 | 44 |

| 150 | 6 | 360 | 280 | 240 | 210 | 3 | 24 | 8-23 | 200* | 450 | 70 |

| 200 | 8 | 457 | 335 | 295 | 265 | 3 | 26 | 8-23 | 240* | 490 | 110 |

| 250 | 10 | 533 | 390 | 350 | 320 | 3 | 28 | 12-23 | 240* | 550 | 220 |

| 300 | 12 | 610 | 440 | 400 | 368 | 4 | 28 | 12-23 | 320* | 600 | 280 |

| 350 | 14 | 686 | 500 | 460 | 428 | 4 | 30 | 16-23 | 320* | 675 | 410 |