Side- Eccentric Hemisphere Valve(Electric)

Technical Parameter

Product model: PQ940F/Y/H

Nominal diameter: DN100~2000mm

Nominal pressure: PN1.0~6.4MPa

Applicable temperature: -29℃~425℃

Applicable media: pulverized coal, coal ash, dust, gas

Flange connection size: GB/T17241.6,BS4504, ISO7005,DIN2501

Structure length: GB/T26146-2010

Manufacturing and acceptance: GB12237-89, API 6D

Pressure test: JB/T9092-1999, GB/T13927-92, API98

Product Detail

Product Structure Features:

Material Of Main Parts

| NO | Part Name | Material name | |||

| 1 | Body/bonnet | WCB | ZG1Cr18Ni9Ti | ZG0Cr18Ni12Mo2Ti | ZG15Cr1Mo1V |

| 2 | Spheroid | WCB+Hard Chrome | 1Cr18Ni9Ti | 0Cr18Ni12Mo2Ti | 25Cr2Mo1V |

| 3 | Stem | 20Cr13 | 1Cr18Ni9Ti | 0Cr18Ni12Mo2Ti | 25Cr2Mo1V |

| 4 | Valve seat | Q235A+PTFE/堆焊 | 1Cr18Ni9Ti/PTFE | 0Cr18Ni12Mo2Ti/PTFE | 25Cr2Mo1V/PTFE |

| 5 | Filler | Flexible graphite | Flexible graphite | Flexible graphite | Flexible graphite |

| 6 | Bolt | 35CrmoA | 0Cr18Ni9 | 0Cr18Ni9 | 15Cr1Mo1V |

| 7 | Nut | 45 | 0Cr18Ni9 | 0Cr18Ni9 | 20CrMo |

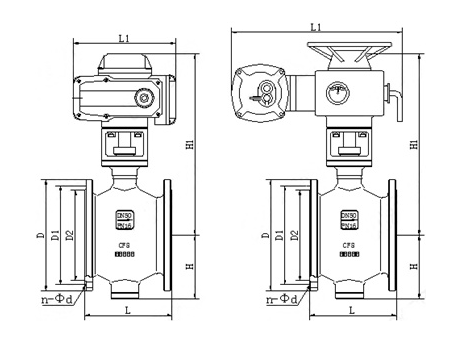

Main External Connection Dimensions

| PN(MPa) | DN | Size(mm) | ||||||||

| L | DSeries 1/Series 2 | D1 | D2 | D6 | b | f | Z-φd | |||

| mm | in | Flange | ||||||||

| 1.0 | 40 | - | 125 | 145 | 110 | 85 | - | 16 | 3 | 4-18 |

| 50 | - | 140 | 160 | 125 | 100 | - | 16 | 3 | 4-18 | |

| 65 | - | 190 | 180 | 145 | 120 | - | 18 | 3 | 4-18 | |

| 80 | - | 178 | 195 | 160 | 135 | - | 20 | 3 | 4-18 | |

| 100 | - | 200 | 215 | 180 | 155 | - | 20 | 3 | 8-18 | |

| 125 | - | 254 | 245 | 210 | 185 | - | 22 | 3 | 8-18 | |

| 150 | - | 267 | 280 | 240 | 210 | - | 24 | 3 | 8-23 | |

| 200 | - | 292 | 335 | 295 | 265 | - | 24 | 3 | 8-23 | |

| 250 | - | 330 | 390 | 350 | 320 | - | 26 | 3 | 12-23 | |

| 300 | - | 390 | 440 | 400 | 368 | - | 26 | 4 | 12-23 | |

| 350 | - | 430 | 500 | 460 | 428 | - | 28 | 4 | 16-23 | |

| 400 | - | 530 | 565 | 515 | 482 | - | 28 | 4 | 16-25 | |

| 450 | - | 580 | 615 | 565 | 532 | - | 30 | 4 | 20-25 | |

| 500 | - | 630 | 670 | 620 | 585 | - | 30 | 4 | 20-25 | |

| 600 | - | 800 | 480 | 725 | 685 | - | 34 | 5 | 20-30 | |

| 700 | - | 900 | 895 | 840 | 800 | - | 38 | 5 | 24-30 | |

| 800 | - | 1000 | 1010 | 950 | 905 | - | 42 | 5 | 24-34 | |