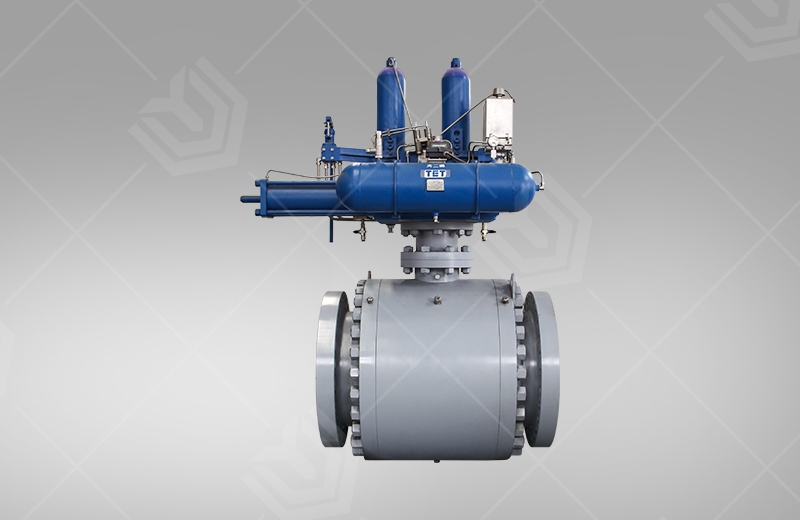

Cast Steel Trunnion Type Ball Valve(Electric)

Technical Parameter

Valve model: Q947F/H

Diameter specification: DN25~700mm

Structural form: two-stage casting valve body

Body material: cast steel (WCB), stainless steel (304, 316, 316L)

Nominal pressure: PN1.6, 2.5, 4.0, 6.4MPa

Applicable temperature: -40℃~425℃

Application scope: petrochemical, gas equipment, power equipment, environmental protection water treatment

Product Detail

Product Design Features

The main structure features include:

Executive Standard

| Design Basis | GB series |

| Design standards | GB/T12237 |

| Flange connection structure length | GB/T12221 |

| Structural length (welded) | GB/T15188.1 |

| Connecting flange | GB/T9113 |

| Butt welding end | GB/T12224 |

| Test and Inspection | GB/T9092 |

Material Of Main Parts

NO | Part Name | Material | |

| GB | ASTM | ||

| 1 | Valve body | WCB | A2116-WCB |

| 2 | Spring | 60Si2aMn | AISI 9260 |

| 3 | Sealing ring | PTFE | PTFE |

| 4 | Gasket | PTFE | PTFE |

| 5 | Blow off nut | 25 | A105 |

| 6 | "0" type seal | Rubber | Rubber |

| 7 | Bottom cover | 25 | A105 |

| 8 | Screw | 35 | A193-B7 |

| 9 | Fixed shaft | 1Cr13 | A276-410 |

| 10 | Plain bearing | PTFE& | PTFE& |

| 11 | Sphere | 1C18Ni9Ti | SS304 |

| 12 | Cap | WCB | A216-WCB |

| 13 | Valve seat | 25 | A105 |

| 14 | Stem | 1Cr33 | A276-410 |

| 15 | Stud | 35CrMoA | A193-B7 |

| 16 | Nut | 35 | A194-2H |

| 17 | Sleeve | 25 | A105 |

| 18 | Filler | PTFE | PTFE |

| 19 | Bracket | WCB | A216-WCB |

| 20 | Packing gland | WCB | A2116-WCB |

| 21 | Key | 45 | AISI C 1045 |

Optional Features

| Explosion-proof function | Protection grade: equivalent to IP65 (or IP67), explosion-proof mark: ExdⅡBT4 |

| Adjustment function | Input and output 4-20mA, 0-5V.DC, 0-10V.DC |

| Manual function | Can be equipped with manual device, valve opening and closing function |

| Relevant temperature | Ambient temperature: -25~+70℃, Ambient humidity: ≤95% |

Main External Connection Dimensions(PN1.6MPa)

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | |

| d1 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 337 | 387 | 438 | 489 | 591 | 686 | |

| L | 165 | 180 | 190 | 216 | 241 | 283 | 305 | 356 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1067 | 1245 | |

| H | 50 | 55 | 80 | 102 | 114 | 127 | 152 | 184 | 219 | 273 | 360 | 395 | 430 | 470 | 550 | 580 | 700 | 800 | |

| Electric | H2 | - | - | - | - | - | - | - | - | 554 | 600 | 652 | 760 | 770 | 830 | - | 940 | 940 | 1115 |

| L1 | - | - | - | - | - | - | - | - | 235 | 235 | 235 | 259 | 400 | 400 | - | 410 | 410 | 410 | |

(PN2.5MPa)

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | |

| d1 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 337 | 387 | 438 | 489 | 591 | 686 | |

| L | 165 | 180 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 502 | 568 | 648 | 762 | 838 | 914 | 991 | 1143 | 1346 | |

| H | 50 | 55 | 80 | 102 | 114 | 127 | 152 | 184 | 219 | 273 | 360 | 395 | 430 | 470 | 550 | 580 | 700 | 800 | |

| Electric | H2 | - | - | - | - | - | - | - | - | 235 | 235 | 400 | 400 | 410 | 410 | - | 420 | 690 | 690 |

| L1 | - | - | - | - | - | - | - | - | 74 | 350 | 350 | 420 | 420 | 400 | - | 400 | 410 | 650 | |

(PN4.0MPa)

| DN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | |

| d1 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 337 | 387 | 438 | 489 | 591 | 686 | |

| L | 165 | 180 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 502 | 568 | 648 | 762 | 838 | 914 | 991 | 1143 | 1346 | |

| H | 50 | 55 | 80 | 102 | 114 | 127 | 152 | 184 | 219 | 273 | 360 | 395 | 430 | 470 | 550 | 580 | 700 | 800 | |

| Electric | H2 | - | - | - | - | - | - | - | - | 235 | 235 | 400 | 400 | 410 | 410 | - | 420 | 690 | 690 |

| L1 | - | - | - | - | - | - | - | - | 74 | 350 | 350 | 420 | 420 | 400 | - | 400 | 410 | 650 | |

(PN6.4MPa)

| DN | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 | |

| d1 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 337 | 387 | 489 | 591 | 686 | |

| L | 292 | 330 | 356 | 406 | 495 | 597 | 673 | 762 | 826 | 902 | 1054 | 1232 | 1397 | |

| H | 114 | 124 | 133 | 159 | 250 | 294 | 395 | 445 | 500 | 530 | 660 | 800 | 900 | |

| Electric | H2 | - | - | - | - | 554 | 574 | 731 | 771 | 867 | 802 | 979 | 1085 | 1148 |

| L1 | - | - | - | - | 235 | 235 | 400 | 400 | 410 | 410 | 420 | 690 | 690 | |