Nominal size: NPS1-48 (DN25-1200)Pressure class: Class150-1500 (PN16-250)Working temperature: -46℃~121℃Main material: carbon steel, stainless steel, alloy steel, etc.End connections: RF, RJ, etc.Applicable temperature: ≤400℃Applicable medium: water, oil, gas, etc.

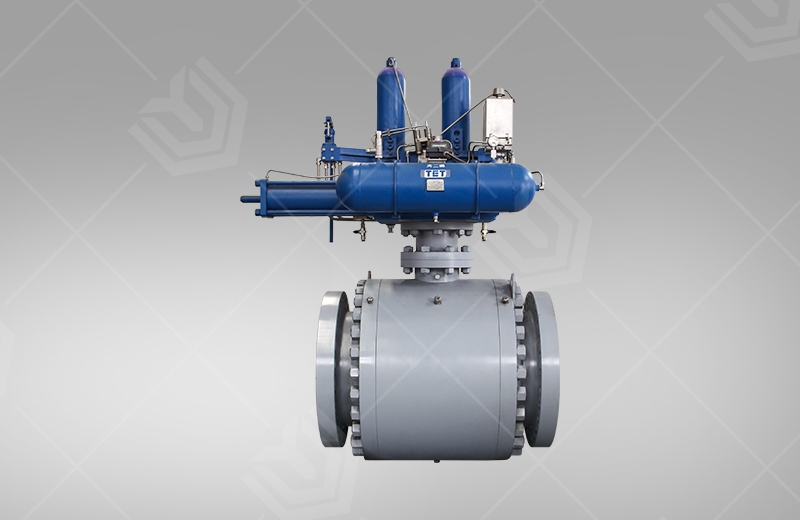

Product Description

Axial flow check valve has the advantages of small flow resistance coefficient, low water hammer pressure, low noise, good flow performance and fast response speed. It is widely used in oil and natural gas long-distance pipelines, compressors and large-scale at the pump outlet. As a key part of the pipeline system, the performance and life of the check valve directly affect the safety of the pump unit and pipeline. Especially the instantaneous speed of the valve disc when the valve is closed directly affects the impact load of the valve disc on the valve seat, and affects the service life and reliability of the valve. When analyzing the dynamic performance of the axial flow check valve, the traditional test method often consumes a lot of time and money, which greatly increases the production cost of the product.

Product Features

Main external connection dimensions

| DN | PN | Flange connection size | Dimensions | ||||

| D | D1 | D2 | b | Z-d | L | ||

| 50 | 16 | 165 | 125 | 99 | 20 | 4-18 | 120 |

| 80 | 16 | 200 | 160 | 132 | 20 | 8-18 | 180 |

| 100 | 16 | 220 | 180 | 156 | 22 | 8-18 | 240 |

| 150 | 16 | 285 | 240 | 211 | 24 | 8-22 | 350 |

| 200 | 16 | 340 | 295 | 266 | 24 | 12-22 | 450 |