Product Model: Z60/61/62H/YNominal diameter: DN125~350mmNominal pressure: PN160-320Working temperature: ≤540℃Design and manufacture: E101, JB/T3595, DL/T531Structure length: E101, JB2766, JB/T15188.1Pressure temperature: E101 JB/T3595Test Inspection: E101Welding groove: JB/T3595, DL/T531 or user provided

Product Description

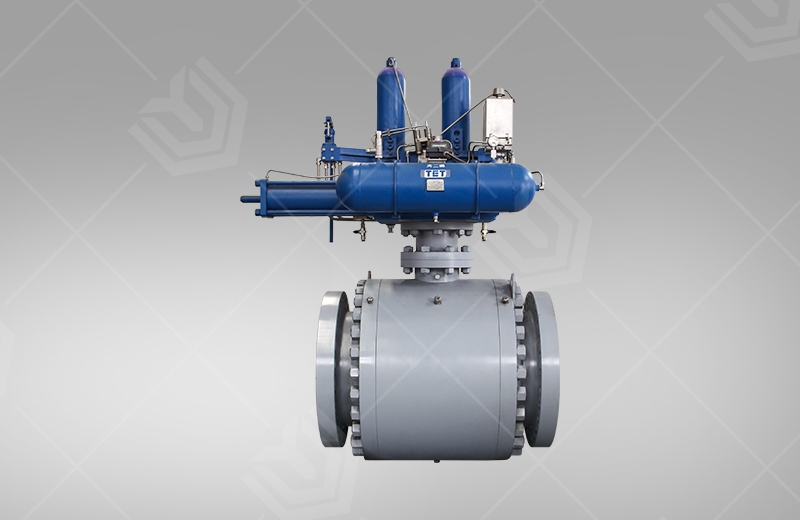

The high temperature and high pressure welded gate valve is a national standard type that follows the JB/T3595 standard. The middle part adopts pressure self-tightening type without bonnet, which has good sealing performance under high temperature and high pressure conditions. There are two materials for the self-sealing ring, one is mild steel, and the other is flexible graphite 316 wire (mesh). The upper layer of the sealing surface is welded drill-base cemented carbide, and the processed pure metal layer is ≥3mm, which has wear resistance, high temperature resistance, corrosion resistance, scratch resistance and long service life. Both ends of the branch pipe are welded structure, and the welding groove can be made according to the standard or user requirements. The valve is suitable for high temperature and high pressure water, steam, oil, superheated steam pipelines in thermal power plants, petrochemicals, metallurgy, etc.

Product Features

1. The shell adopts two process options of forging and casting, with smooth appearance and uniform structure, which meets the requirements of high temperature and high pressure; a full range of full forged steel gate valves can be provided according to user needs;2. Pairing of special materials to ensure high hardness and poor hardness of the sealing surface; precision grinding, as smooth as a mirror, wear-resistant and corrosion-resistant, effectively prolonging the service life;3. The back sealing design can effectively protect the sealing packing and prevent leakage and leakage;4. Multi-channel testing such as high-pressure water strength, high-pressure gas strength, non-destructive testing, etc., comprehensively control the quality of pressure-bearing parts;5. The surface of the valve stem is precision ground and hardened, which is scratch-resistant and corrosion-resistant, effectively reducing the opening and closing torque, and the operation is easier;6. The special corrosion-inhibiting packing structure design is adopted, which is resistant to temperature and pressure, no corrosion, automatic lubrication, reduces the friction of opening and closing, avoids corrosion on the surface of the valve stem, and thus avoids external leakage;7. The two-way pressure-bearing seal design meets the harsh requirements of various special working conditions.The main technical parameters

| PN | Strength test(MPa) | Seal test(MPa) | Proper temperature℃ | Applicable media |

| 16.0 | 37.5 | 27.5 | ≤425 | Water, steam, oil |

| 32.0 | 48.0 | 35.2 | ≤425 | |

| P54/100V | 30 | 11 | ≤540 | |

| P54/140V | 42 | 15.4 | ||

| P54/170V | 48 | 18.7 |

Material of main parts

| 1 | Body | WCB-A105、WC6-12Cr1MoV、WC9-12Cr1MoV |

| 2 | Plate | WCB、WC6、WC9 |

| 3 | Stem | 2Cr13、25Cr2MoV、20Cr1Mo1V1A |

| 4 | Bonnet | WCB-35、WC6-12Cr1MoV、WC9-12Cr1MoV |

| 5 | Platen | 2Cr13、25Cr2MoV、20Cr1Mo1V1A |

| 6 | Packing | Reinforced flexible graphite, V-type PTFE packing |

| 7 | Gland | 1Cr13、WCB、CF8、CF3、CF8M、CF3M |

| 8 | Bracket | WCB、WC6、WC9 |

Main external connection dimensions

| Nominal pressurePN(MPa) | Nominal diameterDN(mm) | Standard value | Reference value | ||

| L | D1 | D2 | H | ||

Z462H/Y | 125 | 600 | 138 | 172 | 1402 |

| 150 | 650 | 160 | 200 | 1129 | |

| 175 | 750 | 181 | 223 | 1250 | |

| 200 | 800 | 202 | 250 | 1450 | |

| 225 | 850 | 232 | 278 | 1650 | |

| 250 | 950 | 275 | 330 | 1750 | |

| 300 | 1194 | 320 | 382 | 1950 | |

Z462H/Y | 125 | 600 | 126 | 172 | 1402 |

| 150 | 700 | 150 | 200 | 1408 | |

| 175 | 750 | 170 | 223 | 1650 | |

| 200 | 800 | 189 | 250 | 1650 | |

| 225 | 850 | 208 | 278 | 1750 | |

| 250 | 950 | 252 | 330 | 1850 | |

| 300 | 1194 | 305 | 412 | 2040 | |

| 350 | 1250 | 353 | 464 | 2150 | |