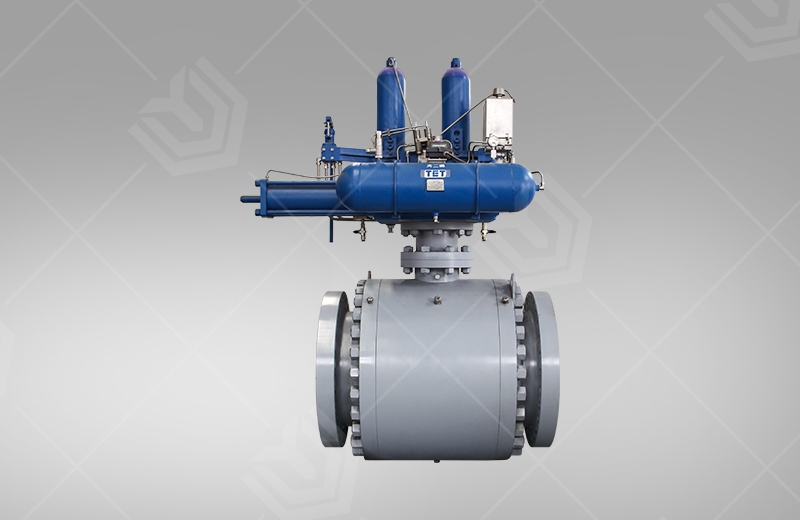

Product model: GWXDF3204YProduct specification: DN50~2000mmPressure rating: PN1.0~2.5MPaApplicable media: air, water, steam, gas, oil, acid, alkali, salt with weak corrosivity, etcApplicable temperature: carbon steel: - 29 ℃~425 ℃ Stainless steel: - 40 ℃~600 ℃Drive mode: worm gear drive, pneumatic drive, electric drive, hydraulic driveMain materials: cast steel, stainless steel, chrome molybdenum steel, alloy steel, dual phase steelDesign specifications: GB/T 12238, JB/T8527, API 608, BSS SP-72Flange connection: GB/T 9113, JB/T79, HG/T20592, ASME B16.47Structure length: GB/T12221, API 609Test and inspection: GB/T13927, API 598

Scope of application

This product is the second generation of two-way hard contact ball valve developed by our company after years of dedicated research and technology cooperation with Zhejiang University and Hunan Changsha University on the basis of the first generation of two-way elastic hard seal ball valve and butterfly valve. The same product has solved two world problems at the same time, that is, the sealing surface of the valve seat and valve plate does not move or deform relative to each other, but resists the medium pressure or differential pressure in both directions, and achieves zero leakage under the condition of hard contact sealing, It has realized the dream that the world valve industry has been striving for for many years and created a new starting point and milestone for the valve industry.This product is widely used in steel, metallurgy, electric power, petroleum, petrochemical, chemical, tap water, paper making, pharmaceutical, environmental protection and other industries and departments.Structural characteristics

The main body of this product is the combination of ball valve and butterfly valve, and the main structure is similar to butterfly valve, while the valve core is part of the sphere, that is, the actual effective part of the valve core from the sphere, that is, the part near the sealing surface. The valve seat is a series ring body, and the rotation center of the valve core is not concentric with the center of the sphere. It can be seen from the profile that the contact between the arc surface of the sphere and the ring cone is a point contact, and a continuous line seal is formed on the solid diagram. However, the contact point between the arc surface of the sphere and the ring cone and the vertical foot formed by the center of the sphere are not perpendicular to the section line of the ring cone. In other words, the sealing surface of the valve seat is not a continuous surface formed by the tangent line of the sphere. When there is a reverse pressure or the reverse pressure is greater than the positive pressure, the back pressure difference will be formed, and the valve seat will automatically compensate the sealing clearance in series, so as to achieve two-way sealing. The greater the applied pressure, the better the effect of two-way sealing.Standards adopted

1. The design shall be in accordance with GB/T12237-2007 Flanged and Butt Welding Steel Ball Valves for General Purpose Valves, GB/T 21385-2008 Metal Seal Ball Valves, GB/T12238-2008 Flanged and Wafer Connection Butterfly Valves for General Purpose Valves, API 608 Flanged, Threaded and Welded Metal Ball Valves, BSS SP-72 Flanged and Butt Welding Ball Valves for General Purpose, API 609 Lug and Flat Plate Butterfly Valves, and MSS SP-67-2002 Butterfly Valves.2. The pressure and temperature rating shall comply with GB/T12224 General Requirements for Steel Valves, API 608 Flanged, Threaded and Welded Metal Ball Valves, and API 609 Lug and Flat Plate Butterfly Valves.3. Flanges shall comply with Raised Face Integral Steel Pipe Flanges (GB/T9113.1-2000), Integral Cast Iron Pipe Flanges (GB/T 17241.6-1998), Cast Iron Pipe Flanges and Flanged Fittings (ASME B16.1), Pipe Flanges and Flanged Fittings (ASME B16.5), Large Diameter Flanges (ASME B16.47), and Round Flanges for Pipe Valves and Fittings (BS4504).4. The structural length shall comply with GB/T 12221-2005 Structural Length of Metal Valves or API 609 Lug and Flat Plate Butterfly Valves.5. The inspection and test shall be in accordance with GB/T13927-2008 Pressure Testing of Industrial Valves or API 598-2009 Inspection and Testing of Valves.6. The electric valve is equipped with manual operation device; The manual device is driven by worm gear.

Main overall dimensions

| Nominal diameterDN | Overall dimensions | Flange size | |||||||||||||

| 0.6MPa | 1.0MPa | 1.6MPa | 2.5MPa | ||||||||||||

| L | H | H1 | D | D1 | Z-d | D | D1 | Z-d | D | D1 | Z-d | D | D1 | Z-d | |

| 50 | 108 | 219 | 130 | 110 | 110 | 4-14 | 165 | 125 | 4-18 | 165 | 125 | 4-18 | 165 | 125 | 4-18 |

| 65 | 112 | 260 | 140 | 130 | 130 | 4-14 | 185 | 145 | 4-18 | 185 | 145 | 4-18 | 185 | 145 | 4-18 |

| 80 | 114 | 267 | 148 | 150 | 150 | 4-18 | 200 | 160 | 8-18 | 200 | 160 | 8-18 | 200 | 160 | 8-18 |

| 100 | 127 | 302 | 162 | 170 | 170 | 4-18 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | 235 | 190 | 8-18 |

| 125 | 140 | 317 | 177 | 200 | 200 | 8-18 | 250 | 210 | 8-18 | 250 | 210 | 8-18 | 270 | 220 | 8-22 |

| 150 | 140 | 332 | 192 | 225 | 225 | 8-18 | 285 | 240 | 8-22 | 285 | 240 | 8-22 | 300 | 250 | 8-26 |

| 200 | 152 | 410 | 228 | 280 | 280 | 8-18 | 340 | 295 | 8-22 | 340 | 295 | 12-22 | 360 | 320 | 12-26 |

| 250 | 165 | 436 | 263 | 335 | 335 | 12-18 | 395 | 350 | 12-22 | 405 | 355 | 12-26 | 425 | 310 | 12-30 |

| 300 | 178 | 300 | 500 | 395 | 395 | 12-22 | 445 | 400 | 12-22 | 460 | 410 | 12-26 | 485 | 370 | 16-30 |

| 350 | 190 | 320 | 510 | 445 | 445 | 12-22 | 505 | 460 | 16-22 | 520 | 470 | 16-26 | 555 | 430 | 16-33 |

| 400 | 216 | 330 | 520 | 495 | 495 | 16-22 | 565 | 515 | 16-26 | 580 | 525 | 16-30 | 620 | 490 | 16-36 |

| 450 | 222 | 380 | 590 | 550 | 550 | 16-22 | 615 | 565 | 20-26 | 640 | 585 | 20-30 | 670 | 550 | 20-36 |

| 500 | 229 | 390 | 610 | 600 | 600 | 20-22 | 670 | 620 | 20-26 | 715 | 650 | 20-33 | 730 | 660 | 20-36 |

| 600 | 267 | 450 | 665 | 705 | 705 | 20-26 | 780 | 725 | 20-30 | 840 | 770 | 20-36 | 845 | 770 | 20-39 |

| 700 | 292 | 480 | 730 | 810 | 810 | 24-26 | 895 | 840 | 24-30 | 910 | 840 | 24-36 | 960 | 875 | 24-42 |

| 800 | 318 | 580 | 910 | 920 | 920 | 24-30 | 1015 | 950 | 24-33 | 1025 | 950 | 24-39 | 1085 | 990 | 24-48 |

| 900 | 330 | 625 | 930 | 1020 | 1020 | 24-30 | 1115 | 1050 | 28-33 | 1125 | 150 | 28-39 | 1185 | 1090 | 28-48 |

| 1000 | 410 | 660 | 1000 | 1120 | 1120 | 28-30 | 1230 | 1160 | 28-36 | 1255 | 1170 | 28-42 | 1320 | 1210 | 28-55 |

| 1200 | 470 | 780 | 1100 | 1340 | 1340 | 32-33 | 1455 | 1380 | 32-39 | 1485 | 1390 | 32-48 | 1530 | 1420 | 32-56 |

| 1400 | 530 | 880 | 1220 | 1560 | 1560 | 36-36 | 1675 | 1590 | 36-42 | 1685 | 1590 | 36-48 | 1755 | 1640 | 36-62 |

| 1600 | 600 | 990 | 1330 | 1760 | 1760 | 40-36 | 1915 | 1820 | 40-48 | 1930 | 1820 | 40-56 | 1975 | 1860 | 40-62 |

| 1800 | 670 | 1090 | 1430 | 1970 | 1970 | 44-39 | 2115 | 2020 | 44-48 | 2130 | 2020 | 44-56 | 2195 | 2070 | 44-70 |

| 2000 | 760 | 1200 | 1540 | 2180 | 2180 | 48-42 | 2325 | 2230 | 48-48 | 2345 | 2230 | 48-62 | 2425 | 2300 | 48-70 |