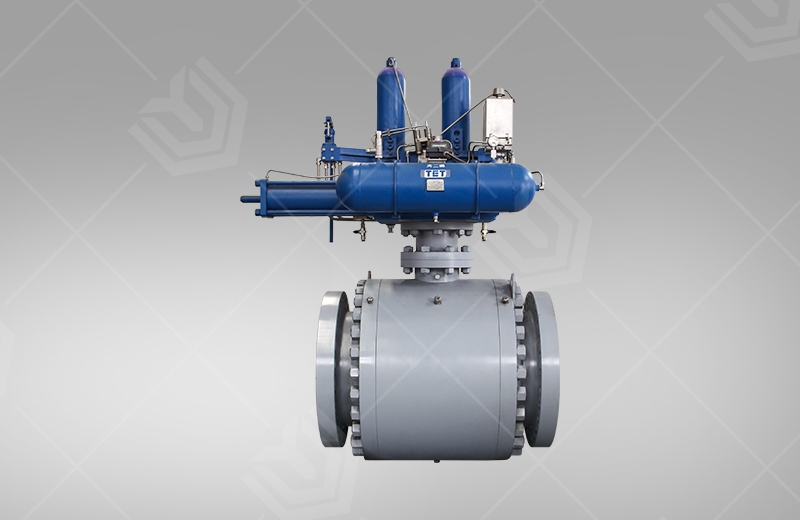

Two way butterfly slag flushing valve

Technical Parameter

Product model: D343SXHNominal diameter: DN50~3000mmNominal pressure: PN1.0~6.4MPaApplicable temperature: - 29~425 ℃Applicable medium: water, steam, oil, etcDrive mode: worm gear drive, electric drive, pneumatic drive, hydraulic driveDesign and manufacturing standards: GB/T 12238, API608, MSS SP-67Structure length standard: GB/T 12221, API609Connecting flange standards: GB/T 9113, GB/T17241.6, ASME B16.5/B16.47Pressure and temperature class: GB/T 12224Test and inspection standards: GB/T 13927, API 598

Product Detail

Scope of application

Advantages of product structure

1. When the sealing pair between the valve seat and the butterfly plate is worn, the adjusting screw can compensate the wear of the sealing pair, ensure the sealing effect, and solve the problem that the existing butterfly valve can only be replaced or returned to the manufacturer for maintenance due to the wear of the sealing pair.When the medium in the fluid channel flows in the reverse direction and the pressure is large, the pressure makes the butterfly plate produce a small amount of displacement. The valve seat under the medium pressure further compresses the compressed spring, and the valve seat is close to the butterfly plate to achieve the reverse sealing effect. In this way, when the medium recovers to the positive flow and the outlet medium pressure decreases, the spring recovers some deformation, ensuring the sealing, and solving the problem of leakage caused by excessive outlet pressure of the valve.2. In the valve, the butterfly plate and the valve stem are connected through the interference fit between the pin shaft and the pin shaft hole. When the butterfly plate is deformed, part of the deformation will be stuck in the groove of the pin shaft. The grooved pin shaft can prevent the axial movement of the pin shaft, thus preventing the problem of falling off and ensuring the smooth opening and closing of the butterfly valve.3. The valve uses V-shaped packing, which can ensure the sealing effect and reduce the opening and closing torque of the valve.Standards adopted

1. The design shall be in accordance with GB/T12,238-2008 Flanged and Wafer Joint Butterfly Valves for General Purpose Valves, API 608 Flanges, API 609 Lug and Flat Plate Butterfly Valves, and MSS SP-67-2002 Butterfly Valves.2. The pressure and temperature rating shall comply with GB/T12224 General Requirements for Steel Valves and API 609 Lug and Flat Plate Butterfly Valves3. Flanges shall comply with Raised Face Integral Steel Pipe Flanges (GB/T9113.1-2000), Integral Cast Iron Pipe Flanges (GB/T17241.6-1998), Cast Iron Pipe Flanges and Flanged Fittings (ASME B16.1), Pipe Flanges and Flanged Fittings (ASME B16.5), Large Diameter Flanges (ASME B16.47), and Round Flanges for Pipe Valves and Fittings (BS4504).4. The structural length shall comply with GB/T 12221-2005 Structural Length of Metal Valves or API 609 Lug and Flat Plate Butterfly Valves.5. The inspection and test shall be in accordance with GB/T13927-2008 Pressure Testing of Industrial Valves or API 598-2009 Inspection and Testing of Valves.Main parts and materials

| Part Name | Materials |

| Body | Cast steel, stainless steel, ductile iron |

| Seat | Stainless steel, hardfacing stellite and other hard alloys |

| Seal ring | Stainless steel and high-temperature resistant graphite plate are combined into multiple layers |

| Stem | 2Cr13 |

| Axle sleeve | Austenitic stainless steel, brass |

| Packing | Flexible graphite, PTFE |

| Packing gland | Cast steel, stainless steel |

| Bracket | Cast steel, stainless steel |

| Disc | Cast steel, stainless steel, ductile iron |

Main external connection dimensions

| Nominal diameter | Structure length(Standard value) | Overall dimension (reference value) | Connection size (standard value) | |||||||||||||

| L | H | D343SXH | D643SXH | D943SXH | PN1.0MPa | |||||||||||

| mm | in | Short | Long | H1 | A1 | B1 | H2 | A2 | B2 | H3 | A3 | B3 | D | D1 | Z-d | |

| 40 | 1 1/2 | 106 | 140 | 107 | 330 | 180 | 180 | 605 | 245 | 72 | 530 | 250 | 255 | 150 | 110 | 4-18 |

| 50 | 2 | 108 | 150 | 112 | 350 | 180 | 180 | 625 | 245 | 72 | 530 | 250 | 255 | 165 | 125 | 4-18 |

| 65 | 2 1/2 | 112 | 170 | 115 | 370 | 180 | 180 | 645 | 245 | 72 | 530 | 250 | 255 | 185 | 145 | 4-18 |

| 80 | 3 | 114 | 180 | 120 | 380 | 180 | 180 | 675 | 355 | 92 | 565 | 250 | 255 | 200 | 160 | 8-18 |

| 100 | 4 | 127 | 190 | 138 | 420 | 180 | 180 | 715 | 355 | 92 | 600 | 250 | 255 | 220 | 180 | 8-18 |

| 125 | 5 | 140 | 200 | 164 | 460 | 180 | 180 | 800 | 355 | 92 | 640 | 250 | 255 | 250 | 210 | 8-18 |

| 150 | 6 | 140 | 210 | 175 | 555 | 270 | 270 | 850 | 250 | 170 | 705 | 300 | 315 | 285 | 240 | 8-22 |

| 200 | 8 | 152 | 230 | 200 | 760 | 400 | 400 | 925 | 250 | 170 | 775 | 300 | 315 | 340 | 295 | 8-22 |

| 250 | 10 | 165 | 250 | 243 | 830 | 400 | 400 | 1035 | 450 | 220 | 945 | 300 | 315 | 395 | 350 | 12-22 |

| 300 | 12 | 178 | 270 | 250 | 895 | 450 | 450 | 1070 | 450 | 220 | 1070 | 300 | 315 | 445 | 400 | 12-22 |

| 350 | 14 | 190 | 290 | 280 | 950 | 450 | 450 | 1190 | 450 | 280 | 1140 | 300 | 315 | 505 | 460 | 16-22 |

| 400 | 16 | 216 | 310 | 305 | 1190 | 535 | 535 | 1250 | 650 | 280 | 1210 | 300 | 315 | 565 | 515 | 16-26 |

| 450 | 18 | 222 | 330 | 350 | 1255 | 535 | 535 | 1295 | 850 | 280 | 1335 | 575 | 714 | 615 | 565 | 20-26 |

| 500 | 20 | 229 | 350 | 380 | 1305 | 535 | 535 | 1455 | 850 | 380 | 1415 | 575 | 714 | 670 | 620 | 20-26 |

| 600 | 24 | 267 | 390 | 445 | 1340 | 570 | 570 | 1585 | 1250 | 380 | 1605 | 656 | 810 | 780 | 725 | 20-30 |

| 700 | 28 | 292 | 430 | 480 | 1520 | 750 | 750 | 1700 | 1250 | 380 | 1844 | 656 | 810 | 895 | 840 | 24-30 |

| 800 | 32 | 318 | 470 | 530 | 1710 | 750 | 750 | 1865 | 1500 | 380 | 2040 | 656 | 810 | 1015 | 950 | 24-33 |

| 900 | 36 | 330 | 510 | 580 | 1810 | 750 | 750 | - | - | - | 2255 | 785 | 863 | 1115 | 1050 | 28-33 |

| 1000 | 40 | 410 | 550 | 650 | 1960 | 900 | 900 | - | - | - | 2380 | 785 | 863 | 1230 | 1160 | 28-36 |

| 1200 | 48 | 470 | 630 | 760 | 2250 | 1000 | 1000 | - | - | - | 2640 | 785 | 863 | 1455 | 1380 | 32-39 |

| 1400 | 56 | 530 | 710 | 850 | 2435 | 1000 | 1000 | - | - | - | 2886 | 810 | 890 | 1675 | 1590 | 36-42 |

| 1600 | 64 | 600 | 790 | 1030 | 2780 | 1000 | 1000 | - | - | - | 3156 | 810 | 890 | 1915 | 1820 | 40-48 |

| 1800 | 72 | 670 | 870 | 1230 | 3020 | 1100 | 1100 | - | - | - | 3421 | 830 | 930 | 2115 | 2020 | 44-48 |

| 2000 | 80 | 760 | 950 | 1350 | 3270 | 1100 | 1100 | - | - | - | 3685 | 830 | 940 | 2325 | 2230 | 48-48 |

| 2200 | 88 | - | 1000 | 1450 | 3470 | 1200 | 1200 | - | - | - | 3885 | - | - | 2550 | 2440 | 52-56 |

| 2400 | 96 | - | 1100 | 1550 | 3670 | 1200 | 1200 | - | - | - | 4055 | - | - | 2760 | 2670 | 56-56 |

| 2600 | 104 | - | 1200 | 1650 | 3870 | 1300 | 1300 | - | - | - | 4260 | - | - | 2960 | 2850 | 60-56 |

| 2800 | 112 | - | 1300 | 1750 | 4080 | 1300 | 1300 | - | - | - | 4490 | - | - | 3180 | 3070 | 64-56 |

| 3000 | 120 | - | 1400 | 1850 | 4280 | 1400 | 1400 | - | - | - | 4690 | - | - | 3405 | 3290 | 68-62 |